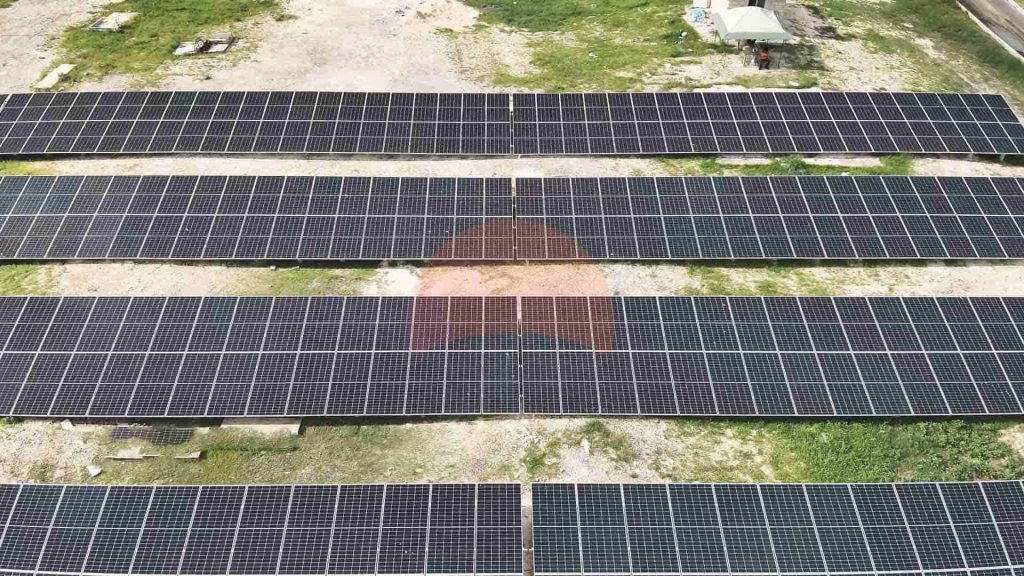

In the heart of the Mexican southeast, under the inclement sun of Merida, Yucatan, a renowned food processor took a decisive step towards energy sustainability. The company, with decades in the sector, was looking to reduce its electricity bill without compromising the continuity of its operations. The solution: a field-mounted 500 kW photovoltaic system.

The challenge

Table of Contents

ToggleThe plant operates almost continuously, and its energy consumption is high, mainly due to cooling systems and automated processing lines. In addition, the terrain available for the installation was not completely flat or uniform, which represented a technical challenge from the start.

The solution

We opted for a groundmount type installation, anchored directly to the ground. To ensure the stability of the structure, a drilling method was used: the ground was drilled to specific depths to insert the structural posts. These poles were cast in place with concrete, guaranteeing long-term resistance to the winds characteristic of the area.

The system was distributed in perfectly aligned rows, optimizing the solar collection throughout the day. High-efficiency solar panels and a centralized inverter were used, which made it possible to maximize performance and reduce points of failure.

Results

Since its commissioning, the system has generated an average of 75,000 kWh per month, covering 65% of the plant’s energy consumption. This has resulted in a reduction in operating costs of more than 50%, not counting the tax benefits associated with investing in clean energies.

In addition to the economic savings, the company has managed to reduce its carbon footprint significantly, improving its image to customers and business partners increasingly aware of the environmental impact.

Brands that trust Solarfy

Seamless deployment

A key aspect of the project was the execution without affecting the daily operation of the company. The excavation, laying and wiring works were carried out in phases, with strict safety controls and coordination with the customer’s technical team.

The system was connected to the internal network through an interconnection under zero export scheme, which allowed surpluses to be injected into the network during off-peak hours, compensating for nighttime consumption.

Measurable and sustainable results

Since its entry into operation, the system has produced a monthly average of more than 75,000 kWh, covering more than 65% of the plant’s electricity consumption. The reduction of the energy bill has exceeded 50% in monthly costs, with an estimated return on investment in less than 4 years.

But it’s not all about money. The company has stopped emitting about 480 tons of CO₂ per year, the equivalent of planting more than 10,000 trees. This has strengthened its positioning as a responsible brand, aligned with increasingly demanding sustainability standards in the food chain.